WBSP002: Growth Opportunities by Rethinking Manufacturing Processes w/ Jason Chester

In this episode, we have our guest, Jason Chester, who shares his thoughts on how evolving consumer trends are forcing manufacturers to rethink their approach to managing manufacturing processes. He also touches on how optimizing your quality operations across the three fundamentals of cost, value, and risk will ensure long term growth, competitiveness and ultimately, profitability.

Finally, he shares why rethinking of approach will enable new manufacturing businesses and SMBs with ambitious growth plans. And how they can leverage the substantial growth opportunities that exist in today’s global consumer society and the frictionless global market.

Chapter Markers

- [0:00] Intro

- [3:17] Overview of Jason’s company

- [4:26] Manufacturing Quality Intelligence?

- [9:44] Why is Quality number one priority for manufacturers?

- [15:35] Overfill vs underfill issue in Quality management

- [19:45] Collaboration of SPC with ERP and MES systems

- [23:01] Right time to implement quality initiatives

- [29:05] 30-60-90 plan for implementing quality initiatives

- [32:22] Closing thoughts

- [33:37] Outro

Key Takeaways

- There are a lot of changes happening in the markets. We’ve got advances in global logistics that are lowering competitive barriers to entry for manufacturers. It’s kind of creating this global single market. We have now online e-commerce and price comparison sites and distribution channels online. This trend is really creating much more frictionless markets for manufacturers.

- An automated production environment isn’t an optimized production environment. We can still get a lot of waste in automation. We can still get poor quality products in automation. An automated production process does what it’s pre-programmed to do, whether it’s filling bottles of source or cans, etc.

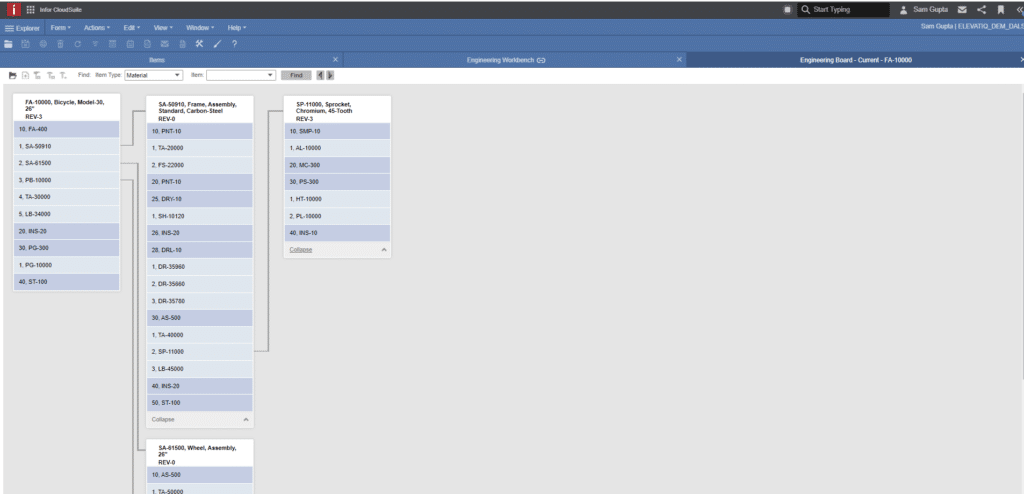

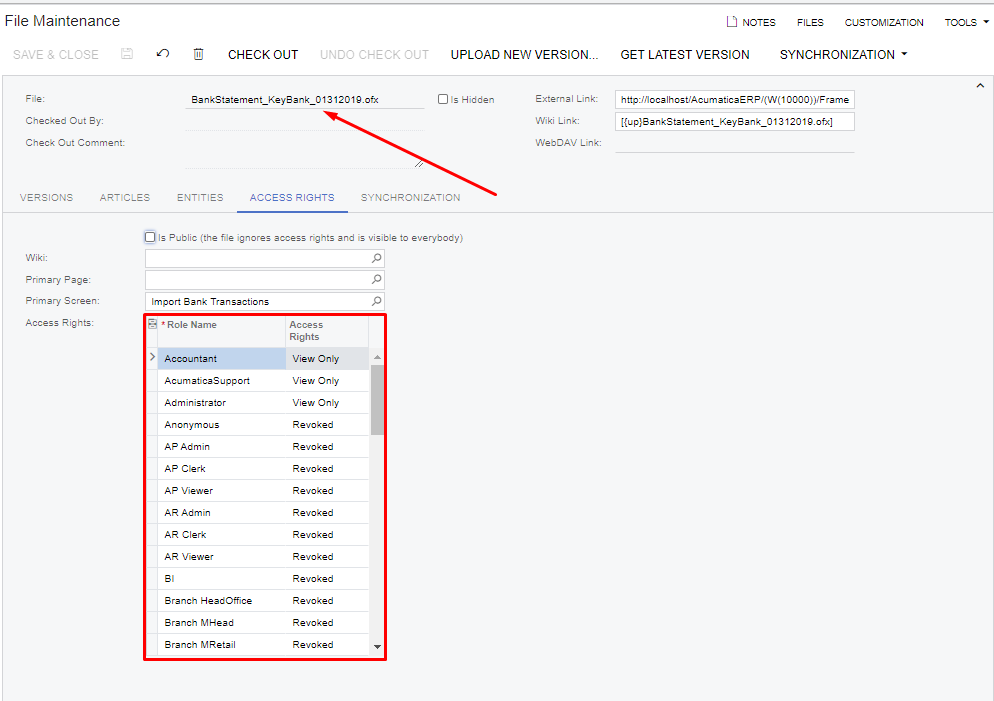

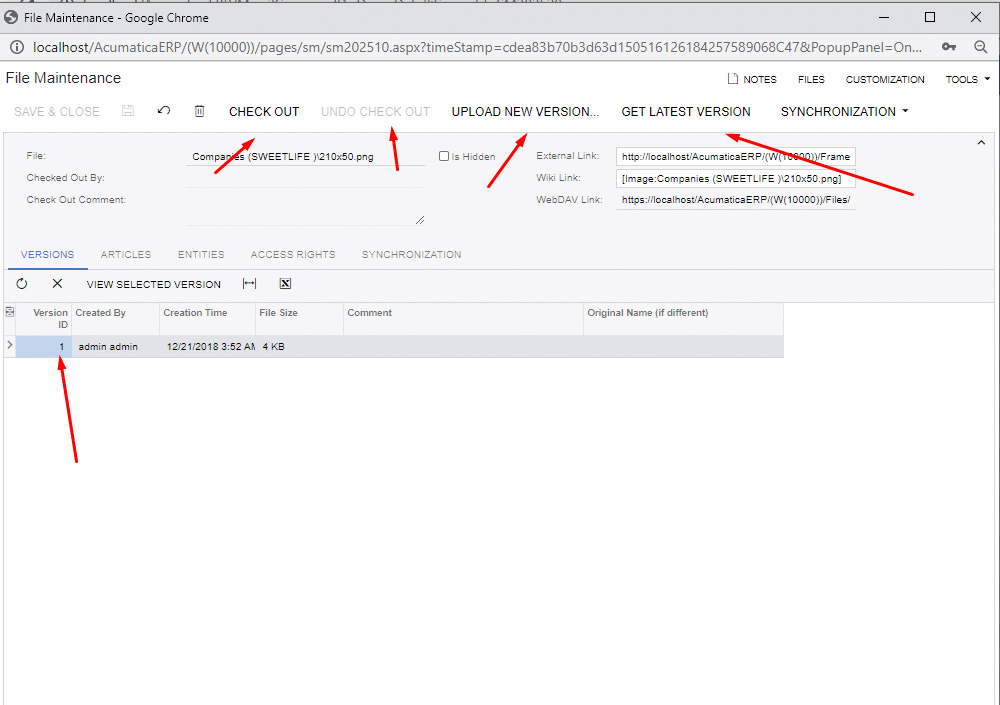

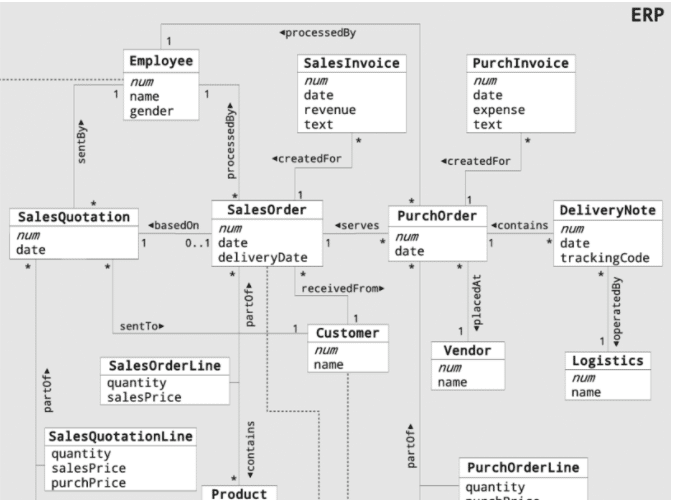

- There is often a lot of confusion about where manufacturing quality intelligence fits with ERP and MES. But typically, MES and ERP systems manage the environment open till a product goes into physical production.

Subscribe and Review

Apple | Spotify | Stitcher | Google Podcasts | Deezer | Player FM | Castbox

About Jason

Jason Chester has over 25 years of experience working directly within the Enterprise IT industry. After starting his career as a software engineer he moved into the IT analyst world. In this role, his work focused on how information technology capabilities can deliver sustainable and transformative business value to end-user organizations.

He now leads the global channel partner operations for InfinityQS, a world leader in manufacturing quality intelligence and Statistical Process Control solutions.

Resources

Full Transcript

Jason Chester 0:00

If we do that sales and marketing promotion, but then we distribute poor quality products out to consumers. That’s going to come back and hurt the manufacturer very significantly very, very quickly.

If we send out products that are not safe for consumption, that’s going to really hurt the manufacturing brand.

Intro 0:18

Growing a business requires a holistic approach that extends beyond sales and marketing. This approach needs alignment among people, processes, and technologies.

So if you’re a business owner, operations, or finance leader looking to learn growth strategies from your peers and competitors, you’re tuned into the right podcast.

Welcome to the WBS podcast where scalable growth using business systems is our number one priority.

Now, here is your host, Sam Gupta.

Sam Gupta 0:55

Hey, everyone, welcome back to another episode of The WBS podcast. I’m Sam Gupta, your host, and principal consultant at digital transformation consulting firm, ElevatIQ.

When we think of growth, we often don’t consider quality as a cornerstone for enabling it, especially in the SMB space. The perceived quality of your products can lead to a poor customer experience, disengaged consumers, and financial implications. All of these factors will have an impact on the P&L and slow your growth down.

Quality Control is of paramount importance for growth for brands seeking the path of DTC. In today’s episode, we have our guest, Jason Chester from InfinityQS, who shares his thoughts on how evolving consumer trends are forcing manufacturers to rethink their approach to managing manufacturing processes, and how by optimizing their operations across the three fundamentals of cost, value, and risk will ensure long term growth, competitiveness and ultimately profitability for new manufacturing business, and SMBs with ambitious growth plans.

Rethinking your approach will enable you to leverage the substantial growth opportunities that exist in today’s global consumer society, and the frictionless global market.

Jason Chester has over 25 years of experience working directly within the enterprise IT industry. After starting his career as a software engineer, he moved into the IT analyst world where his work focused on how information technology capabilities can deliver sustainable and transformative business value to end-user organizations.

He now leads global channel partner operations for InfinityQS, a world leader in manufacturing quality intelligence, and statistical process control solutions.

With that, let’s get to the conversation.

Hey, Jason, welcome to the show.

Jason Chester 3:15

Thank you Sam

Sam Gupta 3:17 – Overview of Jason’s company

Jason, so before we start, as you know, the topic we are going to be discussing today is going to be quality initiatives.

In the quality community, my understanding is that a lot of people know you. They know about your company as well. But what about the other folks and my audience that do not know anything about your company or your background? Would you like to give us a brief about what you guys do and who you help?

Jason Chester 3:43

Yeah, certainly. So InfinityQS, so we’ve been around now for approaching 30 years, we have extensive experience of providing quality intelligence and manufacturing intelligence solutions into manufacturing that is based on statistical process control.

We help clients large and small for multinational manufacturing organizations right down to you know, small single plant manufacturing operations where we utilize fairly advanced data collection, analytics, intelligence, and statistical process control solutions, help them optimize their manufacturing or their production processes. A lot of years of experience in the field.

Sam Gupta 4:26 – Manufacturing Quality Intelligence?

30 years is a very long time, Jason. Okay, so I think I caught a couple of things, and pardon me here because I don’t really have as much familiarity with the quality space and think of me as your manufacturer, and I’m actually trying to understand how I can utilize quality processes for my business.

So I caught some of the terms as per your conversation such as quality intelligence, manufacturing intelligence, they sound fancy but tell me a little bit more about how they can help me

Jason Chester 5:00

Okay, excellent. Yeah, so let’s just take a look at, you know, typical manufacturing organization and the markets that they serve, whether they’re B2B manufacturers or B2C, consumer manufacturers, etc.

You know, there are a lot of changes happening in the markets, they serve, we’ve got advances in global logistics that are lowering competitive barriers to entry for manufacturers. It’s kind of creating this global single market. We have now online e-commerce and price comparison sites and distribution channels online, which are really creating much more frictionless markets, than those manufacturers.

And also the supply-side, you know, we have a lot of, you know, online supply chain hubs and ecommerce platforms and that sort of thing. You know, we have the whole kind of online social media, you know, we have this consumer base that they are now able to influence one another very effectively, where they can rate and review. They can share good and bad stories. They can name and shame brands. You know, even the consumers themselves are shifting. They’re becoming what I call more promiscuous.

And they’re becoming less loyal to brands, and where are the factors take more of a priority. They’re becoming more thrifty. They can be more cost-sensitive, etc, you know. They’re not conscious, conscious consumers. They’re, they’re very, very cognizant towards, you know, recycling, and upcycling, etc. And they’re very ethical now that they shun corporations that have a disregard for the waste and corporate responsibility and environmental responsibility. And they have a voice to be able to share those things across the consumer space, you know, almost instantly to very large numbers, etc.

Jason Chester 6:44

So that is what I kind of collectively call the liberalization of markets. And that’s a very significant change for manufacturers. But equally, there are opportunities as well. New markets are emerging on the back of that new opportunities. You know, opportunities for new products and new innovations, etc, you know, we’ve got new, easy access to emerging economies and emerging markets.

We’ve got a growth in population. And generally, you know, the global economy and wealth growth be, you know, some would argue not equitably, is increasing significantly. And we are genuinely in this kind of era of mass consumption.

So that’s really creating a very challenging environment for manufacturers, and an environment where there’s a lot of opportunity for growth for manufacturers, whether there be small startup manufacturers, or established manufacturers looking to expand into new markets and grow, etc.

And what’s really critical for a manufacturer to be able to address those challenges, and this is why I focus on three really important dimensions, and they are cost, value, and risk.

So cost is obviously really keeping costs as low as possible, reducing waste, reducing resource usage, be more efficient, be more productive. And that obviously doesn’t just impact the profitability of the manufacturing organization but allows them to be more competitive in the markets from a price perspective, etc.

The dimension of value would be about quality, one thing that caught those consumers do demand is better, faster, cheaper. So quality is absolutely paramount. You know, even if we very cost competitive in particular markets, we can’t give way to quality, you know, quality has got to be the number one priority.

Jason Chester 8:29

But value also applies to things like the ability for a manufacturer to be able to adapt to changes in the market, to be more flexible, to be more agile, to provide more capability to get innovative products out to market quickly, etc. And then the risk element falls into two categories.

There are the operational risks that a manufacturer might have, such as you know, operational risks, machine downtimes, quality issues, workforce issues, etc, right through to strategic risks, where potentially, you know, a food safety issue in the case of a food beverage manufacturer, for instance, could really damage brand reputation, or even the cost of quality or safety recalls, product recalls, etc. can be devastating on a business.

So yeah, so really what we do is really help manufacturers to optimize across those three dimensions of cost, value, and risk.

Sam Gupta 9:25

Amazing. So there are a couple of things that jumped out to me based on your conversation, especially the liberalization of the market that’s very new for me.

I did not know that term existed for this one. So maybe we need to have another show for that.

Jason Chester 9:42

Certainly. I would be happy to talk about it.

Sam Gupta 9:44 – why is Quality number one priority for manufacturers?

And the other three dimensions that you mentioned the cost, value, and risk. I think we need to talk a lot more about that. But before that, what I really wanted to discuss is quality being the number one priority.

So as a business owner, my priority is always to get money in my bank account. And the focus of this podcast is really growth for the smaller to medium-sized businesses.

So why is quality the number one priority for me?

Jason Chester 10:11

Well, I think if you look at traditional, or even current manufacturing environments, there’s a heavy emphasis on manufacturing automation. So in recent years, you know, we’ve invested heavily in automating the production process itself, you need very rare now unless it’s an artisan kind of product producer, or whatever, that all of those manufacturing processes manual, you know, even right back decades ago to the introduction of the automated production line, etc, it’s become commonplace.

But an automated production environment isn’t an optimized production environment. We can still get a lot of waste in automation. We can still get poor quality products in automation. An automated production process does what it’s pre-programmed to do, whether it’s filling bottles of source or cans, or making packaging or making components for automotive industry clients, etc. We have this automated production environment, and we’ve gained a lot of benefits.

Over the years from that we’ve displaced a lot of labor, we’ve dramatically increased efficiency, we’ve dramatically increased productivity. But when you look at quality alongside that, the quality process is really unchanged as it was perhaps 10-20-30 years ago, we have this production process going, we have an inspection station, at predetermined intervals, we take a certain number of pieces of products off the production line, we inspect them through various different characteristics and features. And we write down the results on a sheet or we input them into an Excel spreadsheet. Then, we let the line run. And then we’ll test again further down the line.

Jason Chester 11:57

And then at the end of the line, when we’re about to package the product apart or distribute it to the customer, we may do a final inspection of one in 1000 pieces or, you know, one in you know, every hour or something like that, to check that the quality of those products is within specification.

But let me give you an example. Those products may be in specification. But that doesn’t mean say that we’re optimizing that production line. I once worked fairly recently with an alcoholic beverage supplier that filled you know, many, many bottles in a high-speed bottling line. And there are rules and regulations about the fill volumes of content like that, where you know, if you bought a bottle of bourbon, for instance, and it was below the label stated content of 750 milliliters, then you wouldn’t be happy with that as a consumer or neither with the regulators.

So they allow you a certain amount of underfill tolerance, but it’s fairly narrow. So the general trend in the industry is to overfill those bottles, so that they when they get variability in the bottle filling process, they’re not at risk of going below that level stated content allowance.

But imagine that, you know, we’re filling bottles with a lot more product than we actually need to. But technically the product is within specification.

Jason Chester 13:17

And so this particular company, they would monitor that by knowing in a given lot like 8000 bottles, how much volume of liquid is passed through the filler heads and divide that by the number of bottles and the volume of each of those bottles, then is the average on track four would be within specification.

And if it is that batch would be put would be released. If it wasn’t, that whole batch would be scrapped. So that’s 8000 bottles of, alcoholic beverage, which is expensive to produce and, and potentially, you know, lucrative to sell was literally scrapped because that level status, content couldn’t be verified.

So imagine that differently. You know, we only know that process has got inherent variability as we’re checking it. So if we check every 500 bottles, we only know that one bottle in 500 is within specification. And then if there are a problem 1000s of bottles being produced by the time we get to be able to take remedial action to fix the problem. That’s clearly not good.

So you know a with a solution like InfinityQS where we can monitor data in real-time and monitor the variability of those filling processes in real-time, not only can we predict when an out of specification event might occur to enable them to make correct corrective action prior to that specification event becoming an issue but also trying to make the gap narrowed between the overfill and the underfill.

Jason Chester 14:50

So they’re not giving the product away unnecessarily and they’re not at risk of you know, annoying the consumers that buying them refill bottles or causing a problem with the regular lasers for shipping products with not enough content in, etc.

So that’s just an example of where moving away from traditional quality management processes, and through to quality optimization or manufacturing optimization can really make a fundamental difference to the bottom line.

And that’s, you know, just an example of what we see in the industry by taking quality. And bringing that into the 21st century where at the moment, in a lot of scenarios, it’s almost been separate to that investment that we’ve been made be made in automation.

Sam Gupta 15:35 – Overfill vs underfill issue in Quality management

Amazing, when I look at what you just mentioned, the way I’m interpreting this is based on what I have personally seen with the manufacturers, typically when they measure their quality, the process, my understanding is called sampling.

So what they are going to do is they are going to take a couple of sample products to be able to test and those are the only ones that are being tested, and the rest are going to be assumed to be tested. And based on that I think there is going to be a real problem of overfilling and underfilling. And that’s the point that you just mentioned.

So in the case of alcoholic beverages, I can see the problem. But do you see this problem happening with the other industries as well, where we don’t have the problem of overfill versus underfill?

Jason Chester 16:23

Yes, absolutely. I mean, you can see that across all industries. And another example is just taking a step back in, you know, typically, when a quality issue occurs, it’s occurred for a reason there is it’s either a machine problem, or a problem in the process, or a worker that’s made an error on a machine setting, there is some causal factor in that quality event more often than not, and again, you know, you talk about sampling. And you’re absolutely right that products are withdrawn off the line and tested.

But how do we correlate that in real-time to the environment that’s producing that product?

So take a manufacturer of cookies, for instance, you know, we take all of these raw materials, we mix them together in a certain word according to a certain recipe, then we go through certain processes, like forming them into a cookie shape, letting them rest, we then put them through an oven, you know, we then you know, maybe glaze them or dust them with icing sugar or whatever it is, when you get brought bad product off the line is invariable because you know something within that process, as you know, variability has happened or a problem has happened, which has led to that quality event.

But when we just talk about sampling in isolation, we take the product off the line and we determine that it’s not within reasonable limits or within specification limits, etc.

Jason Chester 17:46

But actually, if we monitor the production line, at the same time as you know, the characteristics of the product, then we’re in a much better position to make correlations between right okay, we’re getting these overcooked cookies, because the oven temperature is slightly too high, or the belt speed is slightly too low.

So if we can optimize those manufacturing environment variables, then we’re not going to get a product that’s out of spec in the first place. So that significantly reduces waste.

And I know that that’s another food example but another example might be in, in packaging manufacturers, you know where ingredients into making PT bottles, for instance, you know, have to have a certain ingredients or they’d like a UV, ultraviolet protection additive put in that’s a very expensive raw material.

So they try and limit the amount of UV additive that goes into those products to try and limit obviously waste of a high-value ingredient. But if you have too little, you know, UV protection ingredients in the PET bottles, then inevitably what’s in those PET bottles can spoil either in the distribution channels supply chain or on the in the consumer’s hands for instance, or you put too much in and then you’ve got unnecessary cost in the manufacturing process.

Jason Chester 19:04

So it’s prevalent all around us, you know, we can see in automotive, you know, in automotive components that there are very, you know, strict automotive standards in the tier one automotive OEMs at the supplies that they get.

And unless the product absolutely meets the stringent requirements, the automotive OEM isn’t really that bothered if the 100 products that they’ve ordered, has it taken the manufacturer a sales in previous products to get the 100 good ones or 110 previous ones to get the 100 good products. So it’s all about performance and productivity. And you see it prevalently across all sectors.

Sam Gupta 19:45 – Collaboration of SPC with ERP and MES systems

Okay, I think you touched on several different industries there. Just to recap, you talked about food and beverage then you talked about the automotive industry and the packaging as well. All of the industries could benefit from the real-time quality monitoring that may not be part of their current system that they might be using, especially ERP.

And my understanding of the manufacturing floor is that there are two cases that we see typically with manufacturers. Number one is going to be if they are running the production floor manually, the second is going to be either the combination of ERP or MES.

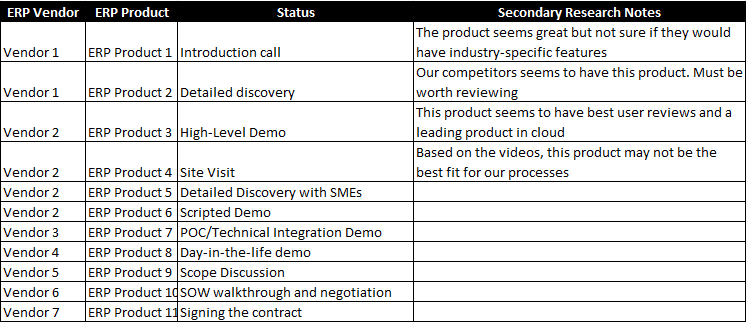

Is that in common in your experience as well? Jason, can you talk a little bit about how your platform would talk to ERP? So let’s say if I’m a manufacturer, and I use ERP, for my quality processes, because I need to gather data related to quality in my ERP. So how would these two systems work together on the production floor?

Jason Chester 20:45

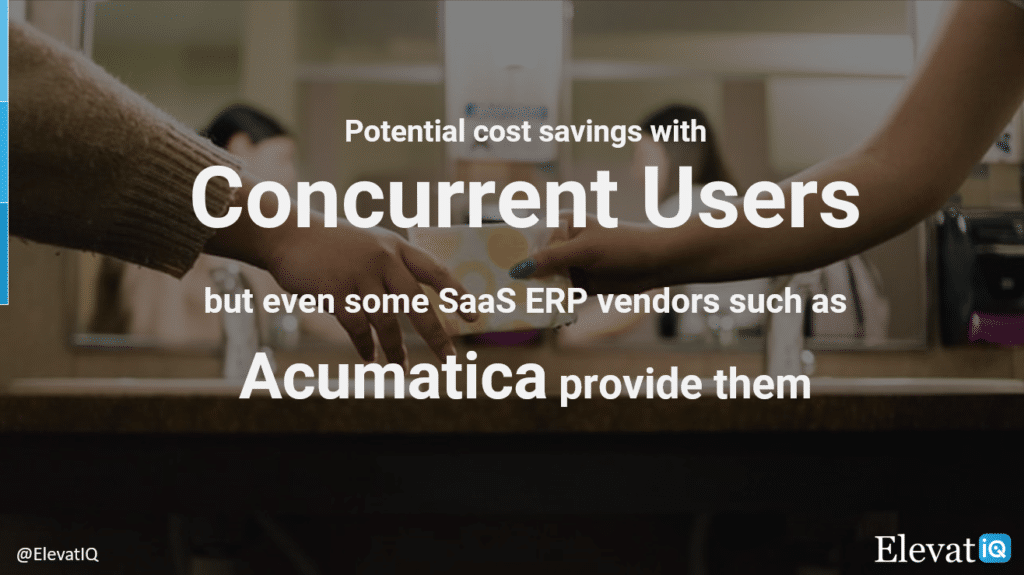

So they are absolutely complimentary. And I think that’s where there is often a lot of confusion or potentially even misconceptions about where manufacturing intelligence fits with ERP and MES. But typically, MES and ERP systems manage the environment open till a product goes into physical production.

So a lot might be released into production and scheduled into production or on a specific line, and there might be, you know, 8000 units of a particular product to be made. And then the final quality inspection characteristics of that lot, and potentially even some sampling characteristics, might then get fed back to the ERP or MES system.

So that in the future, you can look at that particular lot number and see what the final quality inspection characteristics were for its, you know, if there was a customer complaint or, or any other event that needed investigation, etc.

Jason Chester 21:37

But really, that’s where an ERP kind of stops. And we’re really where solutions like InfinityQS begin. Because what we focus on is from when that product goes into production, is really monitoring all of the process environments, and the quality characteristics of that product whilst it is in production, and be able to use in statistical process control, being able to alert to abnormal trends or abnormal variability, to be able to predict when you know, machine settings need to change or when the production environment needs to change, to ensure that we’re keeping that product as close to specification as possible or within the central specification as possible.

And then at the end of that, all of that statistical summary can also then be integrated back into the MES and ERP solution. So it’s really that when the product is in production, where solutions like quality intelligence really come into the room. And obviously, if you scale that up across a manufacturer with multiple lines, or multiple facilities, or even multiple regions, then that all of that information can be aggregated.

So they can compare performance, across processes, across products, etc, to see where you know, the opportunities for improvement. And typically, that is not what ERP solutions are designed to do.

Sam Gupta 23:01 – Right time to implement quality initiatives

Okay, so I think I am convinced of the value of real-time quality monitoring, there’s definitely a value, but I want to shift the gear a bit. And I would like to touch in terms of real hard dollars because we are talking about the growth podcast, right?

So obviously, we can do as many processes as we want, we can implement as much quality as we want. But when is going to be the right time to implement quality for a manufacturer, when I have to compete with my other priorities, such as sales and marketing or R&D?

So what would be your recommendation to implement these quality processes? And which industry? What is the right time to implement the quality initiatives?

Jason Chester 23:42

So I think that the right times when to implement quality initiatives is absolutely right now, I mean, you know, for a manufacturing organization, what those organizations do is manufacture products, the sales, and the marketing and promotional aspects, a route to get those products out to market.

But go back to what we talked about earlier in the sessions, if we do that sales and marketing promotion, but then we distribute poor quality product out to consumers, that’s going to come back and hurt the manufacturer very significantly, very, very quickly. If we send out a product that is not safe for consumption, that’s going to really hurt the manufacturing brand, etc.

Jason Chester 24:22

Or even if we do you know, if we’ve got high volumes of waste, and we struggle with efficiency, and we struggle with you know, output and productivity, then if we get a certain increase in demand because of a successful sales promotion, then we leave consumers wanting because they can’t get that product quickly. Because we’ve got backlogs we’ve got issues in the manufacturing process, etc.

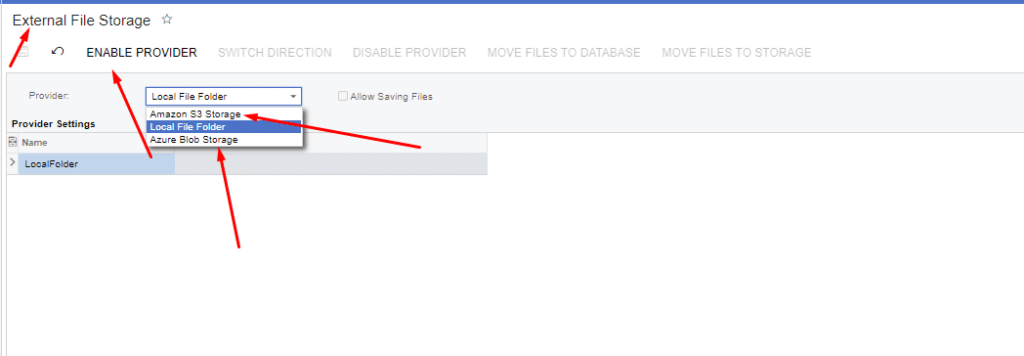

Quality has got to be the underpinning of all of that and it is certainly with you know modern cloud-based implementations of quality intelligence those things can be achieved very quickly. They can be achieved very cost-effectively. The whole notion of digital transformation has been there for a very long time, high cost, high-risk strategy for organizations just simply not true anymore.

You know, we can deploy quality intelligence, very tactically, you know, cloud-based solutions that don’t require, you know, any, any kind of specific infrastructure or investment up front means that you know, we can, we can get in, you know, solving very specific problems in very specific areas, and then potentially expand out those capabilities as the manufacturer needs to or as the manufacturer grows, etc. That’s the beauty of the scalability around the cloud.

Sam Gupta 25:37

Yeah, I think you bring a very good point there with respect to sales and marketing, as business owners, we have a tendency to push a lot for sales and marketing. But I think what matters end of the day is going to be the customer experience. So even if you have your fancy sales and marketing, but let’s say if the customers are receiving the poor quality product, they are not going to come back.

In fact, they might not be able to refer you to other customers because of that experience. Or they might be talking online, I think you brought one element about social media as well, that nowadays customer’s voice is going to be really important too. So let’s say if they have a bad experience with your product, they are going to be talking on social media channels, and word of mouth is not going to be good, which is one of the pillars of influencer marketing.

So I definitely, definitely agree with your point there with respect to thinking of quality as one of the pillars as part of your overall strategy.

Jason Chester 26:33

I couldn’t agree more. Absolutely. And, you know, just reiterate that point around cost value and risk is that you know, we often think in terms of just reducing cost, and just maximizing value and eliminating risk. Actually, that’s quite a misnomer as well, it’s much more complicated than that. This is where it does get quite tricky for manufacturers, because, you know, yes, we can reduce the risk of poor quality product down to almost zero by testing every single product that comes off the line.

But that’s not economical, you know, we can reduce the cost further and further and further down. But it will get to a point where we start to impact on agility and flexibility or will start to impact on product quality, etc. So it’s about achieving that optimal balance between those three dimensions of cost, value, and risk.

And only when a manufacturer has got that optimal kind of state, do they know that they’re absolutely they’ve got the manufacturing capabilities behind their organization to be able to support those sales and marketing initiatives cost-effectively? And you know, and effectively to be able to support whatever it is the business wants to do. If you’ve got a business where you know, the pushing very well on the sales and marketing initiatives and, you know, export initiatives and channels to market and that sort of thing, but they don’t have that top-notch manufacturing capability, then it will rapidly unravel. And that’s how our experience certainly with a lot of manufacturers quality has got to be at the top as a strategy.

Sam Gupta 28:09

Okay, so I really like those three terms, cost, value, and risk. And I’m probably going to take this to the next level. I’m going to create an acronym there for that. And I’m going to call it CVR. I really like that, because that is similar to project management. I think they talk about the triangle where they have similar pillars if I’m not mistaken.

Jason Chester 28:30

Yes. Yes. And, you know, the approach is obviously very common. We’re in an industry that doesn’t shy away from three-letter acronyms. But yeah, I mean, it is a very effective way just to distill a lot of what we talk about down into those three dimensions because I do think it all does boil down to that. And that can be complex. And when you don’t have the tools in place to be able to deal with that complexity.

Inevitably, then it gets overlooked. And it doesn’t get done because it’s seen as a, you know, as a thing that’s too hard to do. And that just isn’t the case with today’s technologies and today’s tools. Okay, amazing.

Sam Gupta 29:05 – 30-60-90 plan for implementing quality initiatives

So I think I’m sold on the value of the manufacturing automation, real-time quality monitoring. I think there’s definitely value with this. But as a business owner, I need to prioritize right, obviously, I have got so many different initiatives.

So I’m actually looking for some sort of actionable advice. And let’s say 30-60-90 day plan, if I want to implement the quality initiatives in my organization, how would you recommend the 30-60-90 approach for me?

Jason Chester 29:33

so we have a very defined methodology internally within InfinityQS. And this is very much around what we call a proof of concept. And we actually have a 30 day, you know, timeframe on our proof of concept. So we aim to work with manufacturers to get them up and running with a proof of concept. And that’s very, very focused in scope.

So it might be a particular production line, a particular product, or a particular process. Where we implement a policy intelligence proof of concept project to address that immediate challenge? So they might choose which process? Or which product? Do they have the most problem with? What do they have the most waste with? What do they have the most variability or in predictability with etc, and really focus on a proof of concept trial, because there is no better way to prove the value to a manufacturing client, than for them to see the value of a solution in their own environment with their own processes, you know, we can provide endless case studies and, and success stories from other sectors and from other industries, but every manufacturer is different, every manufacturing environment is different.

Jason Chester 30:40

So 30 days, you can do a proof focus proof of concept to create that business value proof point internally within your manufacturing organization, then once you’ve done that, that gives you the confidence then that you can scale up, you know, very effectively to other areas.

And this is the beauty of, as I mentioned before, about, you know, cloud-based products now, you know, you don’t need to install, you know, servers and database servers and have a data center provisioned or, you know, new networks put in place. I mean, you know, just a device with an internet browser, and you’re good to go. They’re scalable, they’re elastic, if you know, certainly we’d like InfinityQS, there are no long-term commitments or contracts, you’re not signing up to an annual agreement. It’s a subscription-based product.

Jason Chester 31:27

So, you know, it’s an operational expense, rather than the capital expenditure, you can scale as you scale within the business. You can put a plan in place for focus proof of concept within 30 days, an expanded proof of concept within 60 days, even a full line or full plant pilot within 90 days, and then potentially an enterprise-wide rollout within six to 12 months.

So very, very fast, very fast time to value very scalable, and very cost-effective. You know, and again, the final point on that is that demand obviously changes. You know, as we’ve seen this year with the pandemic, demand can be up and down. And so can usage of cloud-based solutions, like quality intelligence, you can acquire and more licenses when required and reduce that license count when they’re not required. And that works well as well for seasonal manufacturers, as well.

Sam Gupta 32:22

Okay, amazing. So one thing that jumped out to me, overall, from the show is each manufacturing environment is different. And I couldn’t agree more with that. So with that, Jason, I think, you know, we are done with the show. Do you have any last-minute thoughts that you would like to share with the audience?

Jason Chester 32:40

No, I think there’s been a great conversation, there are a lot of opportunities, I guess the only point I would share is that you know, whilst every manufacturer is different manufacturers can also learn from other companies, even in different sectors, we talked earlier about the difference between food and beverage or automotive components or, or packaging manufacturers, etc.

Whilst there are a lot of differences. There are also a lot of similarities. And you might learn techniques around quality in one industry that can be applied with great effect to another industry. So that kind of cross-pollination of techniques and ideas from different industries can be really important as well.

Sam Gupta 33:20

Yeah, I cannot agree more with the cross-pollination aspect of learning. I think that’s the foundation of learning in my mind.

So again, thank you so much, Jason, for your time, really appreciate it. And you have a wonderful day.

Jason Chester 33:32

You too. It’s been a pleasure and enjoyable having this conversation.

Sam Gupta 33:37

I cannot thank our guests enough for coming on the show and sharing their knowledge and journey. I always pick up stuff from our guests, and hopefully, you learn something new today. If you want to know further about Jason, or InfinityQS, please visit infinityqs.com. They are currently offering three months free trial of their real-time quality, intelligence, and statistical process control software called Enact if you’re interested in trying for your quality operations. Links and more information will also be available in the show notes.

If anything in this podcast resonated with you and your business, you might want to check other related episodes, including the interview with Michael Begg from AMZ advisers, who brings a unique perspective on D2C from Amazon as a marketing channel. Also the interview with Chase Clymer from Electric Eye, who touches on D2C from the e-commerce toolset and architecture standpoint.

Also, don’t forget to subscribe and spread the word among folks with similar backgrounds. If you have any questions or comments about the show, please review and rate us on your favorite podcasting platform or DM me on any social channels. I’ll try my best to respond personally and make sure You get help.

Thank you, and I hope to catch you on the next episode of The WBS podcast.

Outro 35:07

Thank you for listening to another episode of The WBS podcast. Be sure to subscribe to your favorite podcasting platform so you never miss an episode. For more information on growth strategies for SMBs using ERP and digital transformation, check out our community at wbs.rocks. We’ll see you next time.