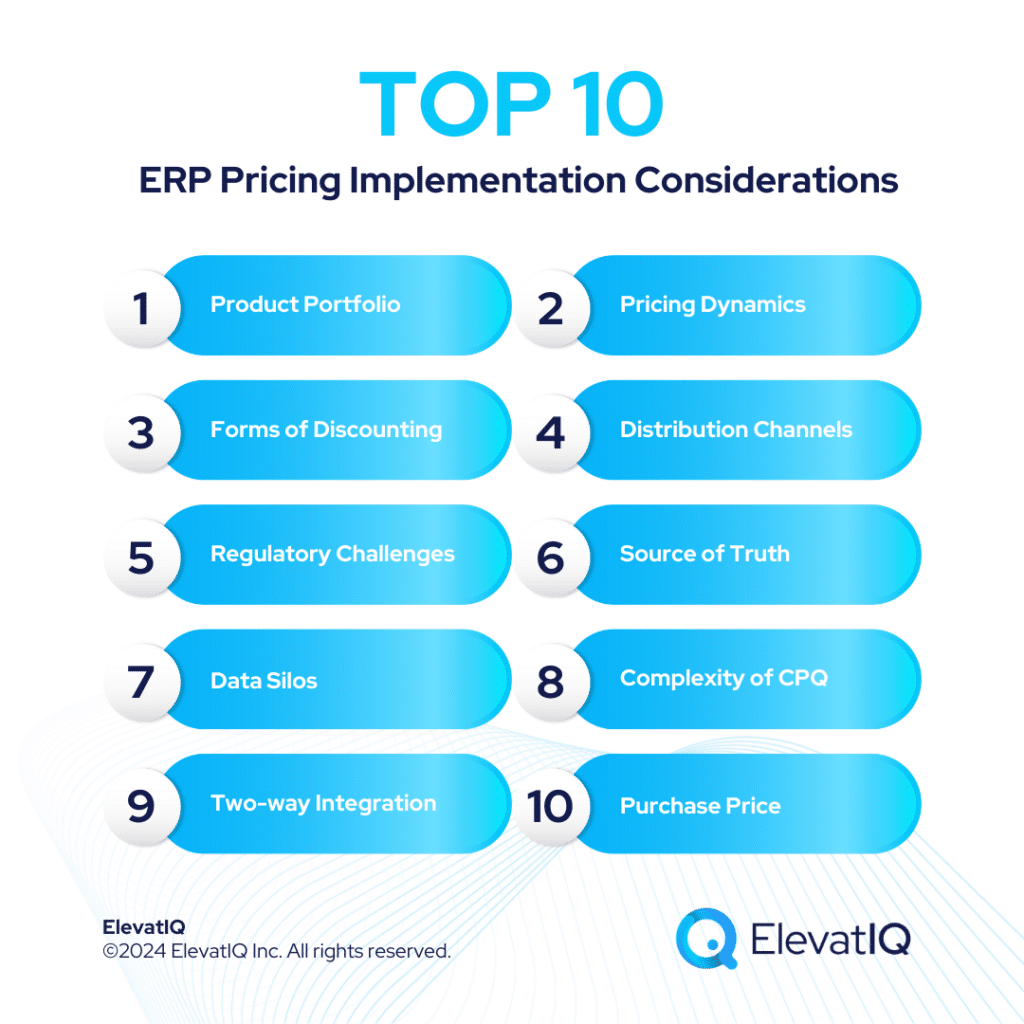

Top 10 ERP Pricing Implementation Considerations

ERP pricing implementation is not as easy. It brings forth many challenges. Some of them include managing and integrating vast amounts of pricing data, ensuring pricing consistency across various platforms, keeping pricing information up-to-date in real time, staying compliant with industry regulations, and so on. The list goes on. When it comes to pricing, ERP systems have several business rules at various levels. And understanding the nuances of these layers is crucial for pricing to work as your expectations.

When we talk about ERP pricing implementation, it helps in supporting complex pricing structures and provides the users with the most accurate experiences. It creates a seamless experience between operations and customer experiences. Enabling ERP pricing implementation means customers are receiving the most accurate pricing data that helps them with their purchase decisions. Businesses also gain the freedom to tier their pricing and discounts catered to certain customers and manage their sales. This blog delves into the top 10 ERP pricing implementation considerations.

1. Product Portfolio

While ERP pricing implementation, one of the critical factors that can significantly impact the integration is the intricacy of your product portfolio. For example, a company will face multiple challenges if it has a diverse product range. The need for multiple pricing tiers arises when dealing with various products, especially customizable ones. In this case, the company will have to publish the pricing in the market configure pricing in the ERP system, and e-commerce pricing. The result will be a complex web of pricing structures, leading to confusion in customer-facing situations.

The customer’s ordering experience will become a puzzle. This is because pricing depends on the channel through which the opportunity flows into the system. This will create challenges in managing repeat orders and introduce manual processes, making consistency a rare commodity. The lesson learned here is clear. When navigating the ERP pricing implementation, it’s crucial to streamline and simplify your product portfolio.

Strategies to Simplify Product Portfolios

- Assess the performance of each product, identify the top-performing products, and consider phasing out those that contribute minimally to revenue.

- Concentrate on your core products that align with your brand identity and meet the primary needs of your target audience.

- Identify and eliminate redundant or overlapping products that serve similar purposes.

- Listen to customer feedback and analyze demand patterns. Use this information to prioritize products that are in high demand.

- Regularly review the lifecycle of each product. Consider discontinuing products that are at the end of their lifecycle and invest in innovation for new ones.

- Create bundled offerings or packages that group related products together. This not only simplifies the purchasing decision for customers but also helps in promoting specific product combinations.

2. Pricing Dynamics

When we talk about pricing dynamics, several factors come into play, each influencing the cost structure and strategies employed by distributors and manufacturers. Understanding and navigating these diverse pricing dynamics are crucial during ERP pricing implementation. This understanding enables effective configuration of the ERP systems to accommodate different pricing structures. It also helps align them with the specific needs of the business. It also ensures pricing data accuracy and consistency within the ERP system. Businesses can adopt more customer-centric pricing strategies when they understand the pricing dynamics properly. They stay adaptable to market changes or shifts in demands and competition.

Key Dimensions in the Pricing Equation

- Base Pricing. The foundation of any pricing strategy is the base pricing set by the distributor or manufacturer. This serves as the initial benchmark for products, reflecting their inherent value and influencing subsequent pricing adjustments.

- Warehouse-Based Pricing. Introducing another layer of complexity, warehouse-based pricing depends on the geographical location of a warehouse. The same product may be priced differently based on the region or country where the warehouse is situated. This dynamic is driven by logistical considerations, regional cost variations, and market demands specific to each location.

- Customer-Based Pricing. Adopting a customer-based approach, products are priced differently depending on the target audience. For retail customers, prices factor in elements like demand, competition, and perceived value for end consumers. Distribution customers, purchasing in bulk, face a different pricing structure. Manufacturers or distributors need to consider providing margins to accommodate the larger volumes bought by distributors, aligning pricing strategies with the distinct needs and purchasing behaviors of various customer segments.

- Seasonal or Event-Based Pricing. Introducing a temporal dimension to the pricing equation, seasonal or event-based pricing strategies mean products may be priced differently during specific seasons, festivals, or events. This reflects the fluctuating demand and market dynamics tied to these timeframes.

3. Forms of Discounting

Discounting serves as a strategic layer atop the pricing structure, offering businesses a nuanced approach to adjust product costs and respond to various market dynamics. The ways that different forms of discounting affect the ERP pricing implementation are similar to how the pricing dynamics affect it. But there are some additions to it. Understanding this concept also helps businesses optimize costs in response to regional market demands. It helps in customer segmentation for more personalized and effective pricing.

Key Dimensions in the Discounting Framework

- Base Discount. Applying a percentage reduction to the foundational base pricing, the base discount serves as a dynamic tool. It allows businesses to maintain a clear baseline for product values while introducing flexibility and responsiveness to market conditions, ensuring competitiveness without compromising perceived product value.

- Location-Based Discounts. Providing an additional dimension to the discounting framework, location-based discounts optimize costs in response to regional market demands. These discounts tailor pricing strategies to specific warehouse locations, addressing pricing variations influenced by logistical, operational, or market-specific considerations.

- Customer-Based Discounts. Extending adaptability to different customer segments, customer-based discounts cater to the unique needs of retail and distribution customers. This approach allows businesses to foster stronger relationships, enhance market penetration, and customize pricing for individual and bulk purchases.

- Event-Based Discounts. Tied to seasons, festivals, or specific occasions, event-based discounts introduce a time-sensitive element. This dynamic enables businesses to align pricing strategies with the pulse of the market during specific periods, providing the agility to respond effectively to changing market dynamics.

4. Distribution Channels

Industries operating through multiple distribution channels, involving layers like manufacturers, distributors, and retailers, face unique challenges in devising pricing strategies. Each channel requires tailored pricing structures to address the distinct needs of intermediaries and end customers. This complexity is heightened without a unified pricing management system, making navigating and managing diverse pricing models effectively challenging. This disparity necessitates centralized control for effective management, especially considering the underlying thread of inventory that ties everything together.

5. Regulatory Challenges

Companies in sectors like healthcare, finance, or pharmaceuticals are bound by stringent regulations that significantly influence pricing strategies. Regulatory requirements may demand transparency in pricing, impose controls on pricing structures, or mandate compliance with specific pricing guidelines. Navigating these regulatory intricacies while maintaining competitive pricing adds complexity for businesses. As businesses strive for a unified and consistent pricing approach, navigating the regulatory landscape becomes critical to successful ERP pricing implementation.

6. Source of Truth

Ensuring a seamless ERP pricing implementation hinges on having a single, authoritative source of truth for pricing data. The ERP system emerges as this bedrock, embodying the most current and accurate pricing information. An architectural approach is often advocated that minimizes manual touches and ensures the fewest number of interactions. The crux lies in understanding the internal implications and how the architecture aligns with customer needs.

Despite potential organizational resistance, establishing the ERP as the unambiguous source of truth is the key to internal and external satisfaction. The critical role of the ERP system in pricing integration is magnified, particularly in contrast to the pitfalls of relying on third-party systems or maintaining pricing information in disparate locations. This narrative reinforces the need for a centralized control mechanism, emphasizing the ERP as the linchpin for consistent and accurate pricing across diverse channels.

7. Data Silos

A critical factor demanding attention is the emergence of data silos when utilizing pricing software or external tools, especially in contexts involving dynamic pricing or intricate formulas. A centralized source of truth is of utmost importance to prevent the potential pitfalls of neglecting consistent auditing within the ERP. The pricing information residing in various channels such as published pricing in the market, ERP-configured pricing, and e-commerce pricing, introduces challenges in maintaining consistency and accuracy, particularly when dealing with repeat orders from different channels.

8. Complexity of CPQ

Integrating CPQ systems requires extensive product details, customer information, and pricing data. Notably, sales and marketing teams resist direct engagement with ERP systems for quoting, further complicating the integration process. The inherent complexity of CPQ systems demands meticulous integration work, creating two-way loops within the ERP architecture. This further underscores the critical importance of addressing the challenges posed by CPQ integration to ensure a streamlined and efficient ERP implementation.

Some of these complexities involve data inconsistencies, the need to handle things externally, and the importance of having a structured pricing process. While there may be differences in opinions regarding the integration’s feasibility, the consensus is that maintaining a clear master-slave relationship, with the ERP system being the master, can help ensure successful ERP pricing implementation.

9. Two-way Integration

The criticality of seamless connectivity between CPQ systems and ERP involves a sophisticated two-way data flow mechanism where pricing details undergo dynamic changes based on evolving product configurations and customer requirements. Failure to consistently audit and manually check the ERP system introduces a cascade of problems, with a specific example illustrating challenges related to published pricing, ERP-configured pricing, and e-commerce pricing. The complexity arises when determining how to price an order, depending on the channel through which the opportunity is initiated. This manual process can lead to discrepancies, especially in repeat orders, creating a compelling argument for centralizing data within the ERP system.

10. Purchase Price

Navigating the landscape of ERP pricing implementation involves not only addressing pricing complexities on the sales side but also delving into the often-overlooked realm of the purchase price. The interconnected nature of the buying and selling sides of the business is often emphasized, stressing the importance of aligning these aspects to ensure overall consistency and efficiency. This advocates for a centralized control system within the ERP, despite potential challenges in getting the entire organization on the same page. It argues that treating the ERP as the source of truth for pricing data, even when residing in different channels, leads to better internal and external service in the long run.

Conclusion

In conclusion, the blog stresses the need for businesses to address the challenges of ERP pricing implementation and advocates for centralized pricing data to mitigate these challenges. It emphasizes the impact of discounting forms, the intricacies of managing distribution channels, and the influence of regulatory requirements on pricing strategies. The central theme revolves around establishing the ERP system as the authoritative source of truth for pricing data. Despite potential resistance, the blog asserts that making the ERP the linchpin for consistent and accurate pricing across diverse channels is vital for internal and external satisfaction. It advocates for a centralized control mechanism within the ERP, underscoring its critical role in successful pricing integration.

Moreover, if you are contemplating ERP pricing implementation, it is essential to consider the factors that may impact your outcomes in the future. Understanding the dynamics of pricing and discounting adds another layer of insight to inform this decision-making process. Armed with this knowledge, you’ll be better equipped to engage in a meaningful and informed discussion with independent ERP consultants who serve as subject matter experts in this field. Collaborating with experienced ERP consultants becomes a strategic step in optimizing your pricing strategies and fostering a streamlined integration that stands the test of time.