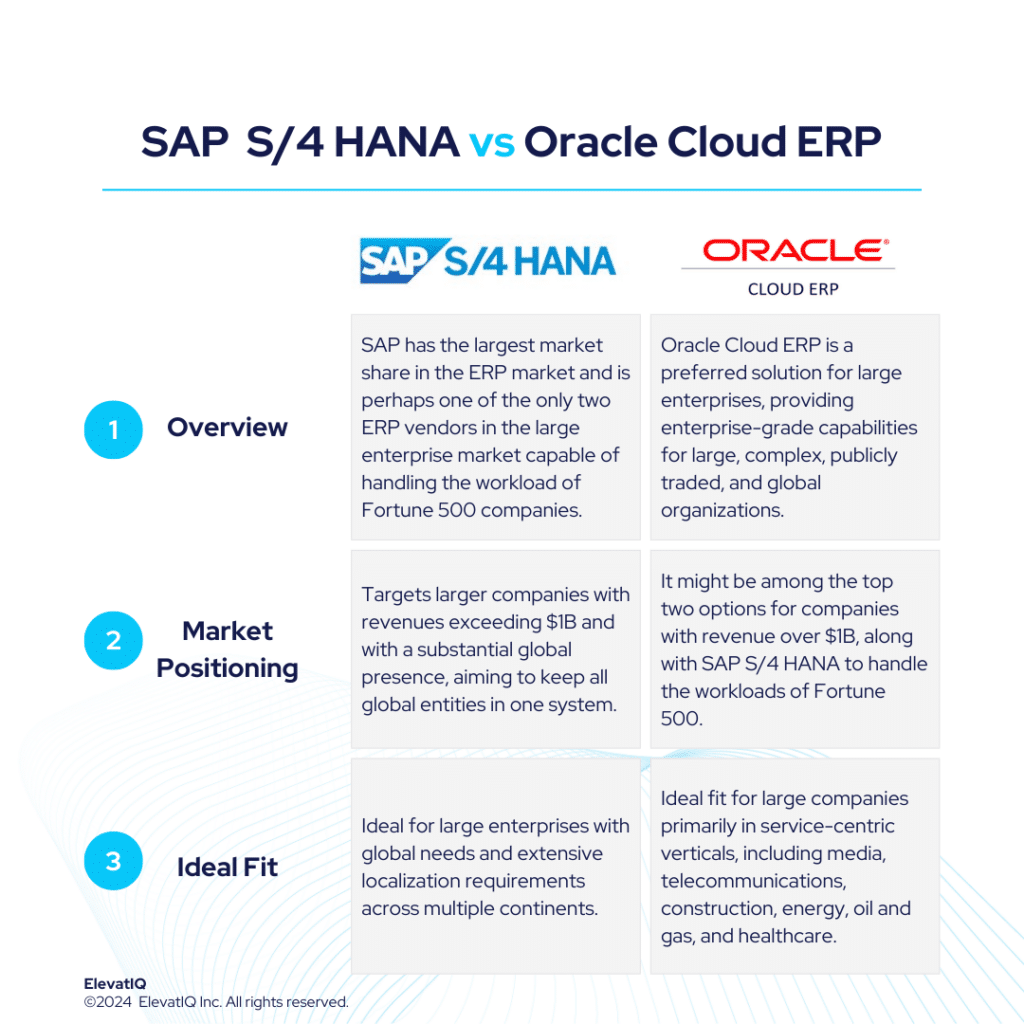

SAP S/4 HANA vs Oracle Cloud ERP Independent Review 2024

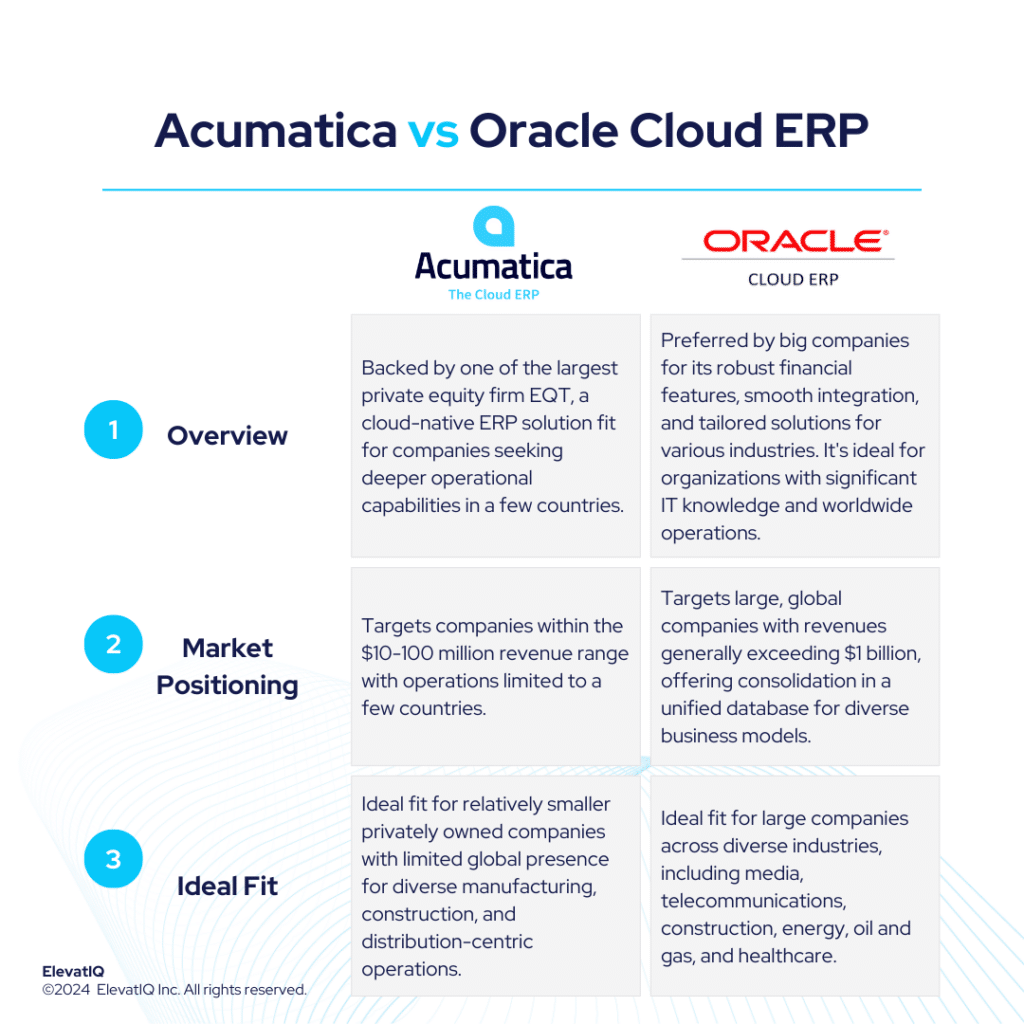

The architecture that goes along with the SAP S/4 HANA Suite is what enterprise-grade companies are likely to prefer, including leading products such as SAP SuccessFactors for HCM, SAP Hybris for Commerce, SAP EWM for WMS, Ariba for P2P, and Concur for T&E. On the other hand, Oracle ERP Cloud remains a top choice for large companies across diverse industries, particularly media, telecommunications, construction, energy, oil and gas, and healthcare. Despite the need for internal IT expertise, it is also suitable for companies that need to integrate various third-party ERP add-ons.

SAP S/4 HANA may be among the only choices for enterprise companies, especially strong for product-centric enterprises where mature capabilities such as MRP and allocation would be a must-have. Whereas, Oracle Cloud ERP particularly caters to companies needing ledger-level security and hierarchical financial reporting. Additionally, Oracle Cloud ERP seamlessly integrates a powerful HCM solution along with a natively integrated EPM solution. SAP S/4 HANA is also one of the strongest solutions for companies that might operate in multiple countries and require these entities hosted in one database. So, if you have narrowed down your choices between SAP S/4 HANA vs Oracle Cloud ERP, this comparison looks under the hood and provides crucial information for your ERP selection project. So, let’s dive in?

| SAP S/4 HANA | Oracle Cloud ERP | |

| Started in | Pioneers of ERP | Established enterprise software company |

| Ownership by | SAP | Oracle |

| No. of customers | 28000+ | 10,000+ |

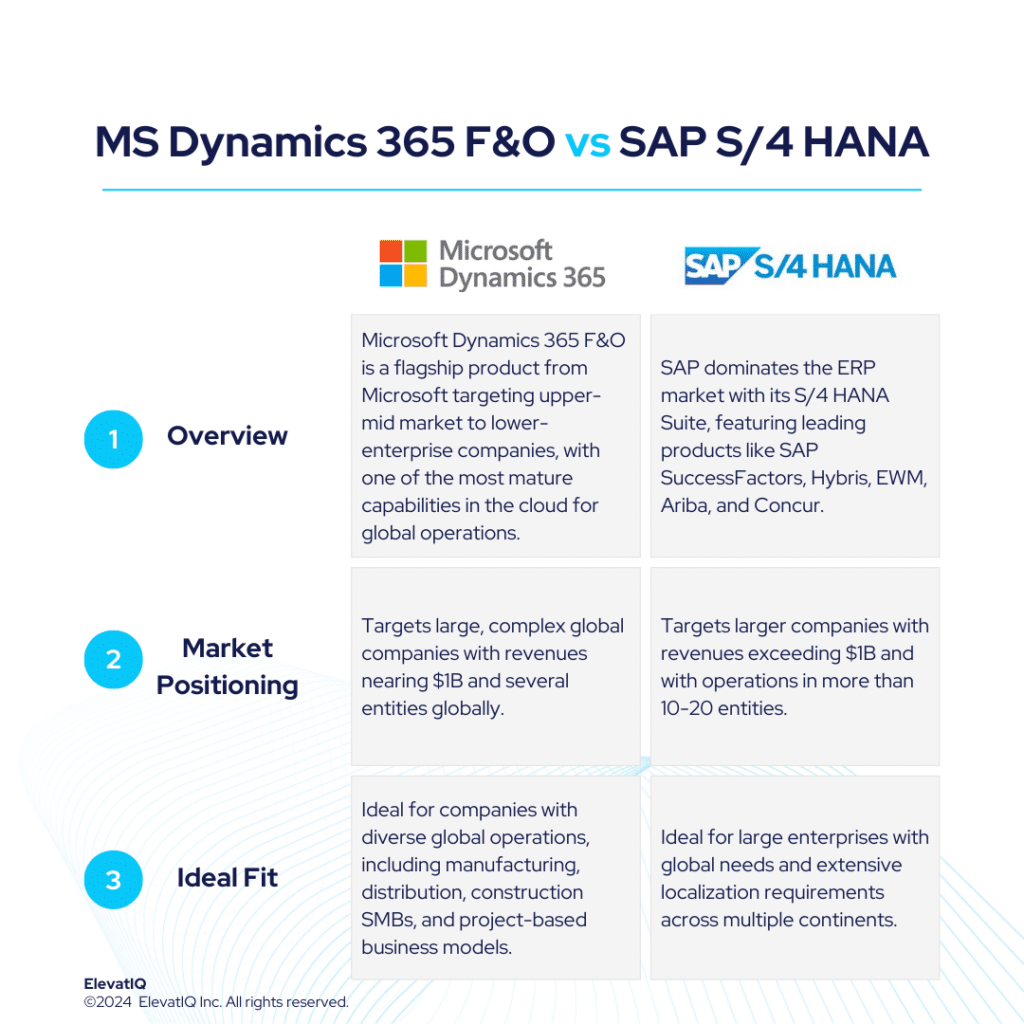

What Is SAP S/4 HANA?

SAP S/4 HANA remains the top choice for large enterprises particularly with global needs and extensive localization requirements across multiple continents. Although in this league, its primary rival is Oracle. While alternatives like Unit4, IFS, or Deltek might handle the workload for larger enterprises, they often lack the robust global compliance and transactional capabilities that SAP S/4 HANA offers. Additionally, SAP S/4 HANA excels in providing superior transactional workflow capabilities that are purpose-built to streamline traceability for large and complex organizations.

Moreover, SAP S/4 HANA is an ideal choice for companies seeking a best-of-breed architecture tailored to the needs of specific functions. This architecture allows for operational cores on different ledgers, which is also crucial for larger distribution and 3PL companies managing complex WMS networks. Companies with intricate HCM operations and stringent compliance requirements may particularly find it necessary to integrate a best-of-breed system.

Additionally, for enterprises requiring sophisticated eCommerce platforms with components like CDP or CPQ, SAP S/4 HANA provides the essential capabilities. The flexibility and enterprise-grade best-of-breed architecture also makes SAP S/4 HANA a standout solution for such diverse operational needs. Although, the cloud version may require additional third-party add-ons, similar to NetSuite. Nevertheless, organizations opting for the on-prem version can access superior capabilities, potentially outperforming other ERP systems.

What is Oracle Cloud ERP?

Oracle ERP Cloud remains a top choice for large companies across diverse industries, particularly media, telecommunications, construction, energy, oil and gas, and healthcare (post-acquisition of Cerner). It is particularly suitable for organizations with substantial internal IT expertise and a requirement for integrating various proprietary and third-party ERP add-ons, such as patient claims management or utility billing solutions.

Oracle ERP Cloud is well-suited for global companies using it as their corporate financial ledger while employing other systems at the subsidiary level. Its robust financial capabilities cater to companies needing ledger-level security and hierarchical financial reporting, such as LOB, functions, or funds. Additionally, it seamlessly integrates a powerful HCM solution along with a natively integrated EPM solution.

Oracle ERP Cloud excels in risk management, advertising, and Cx cloud, particularly catering to industries like financial services and insurance. While it is a superior fit for service-centric industries, its success in product-centric industries has been limited. Often used as a corporate ledger, it might deploy another operationally rich solution at the subsidiary level in certain industries. Despite its strength for large enterprises, Oracle ERP Cloud is not the ideal choice for SMB customers.

SAP S/4 HANA vs Oracle Cloud ERP Comparison

Navigating the choice between SAP S/4 HANA vs Oracle Cloud ERP is a significant decision for businesses particularly looking for operational efficiency and strategic alignment. Thus, this section delves into the comprehensive comparison of SAP S/4 HANA vs Oracle Cloud ERP across various critical dimensions.

| SAP S/4 HANA | Oracle Cloud ERP | |

| Global Operational Capabilities | Has deeper multi-entity capabilities. | Hosts multiple entities globally in one database. |

| Diverse Capabilities | Handles diverse business models, might need add-ons for deeper operational capabilities. | Accommodates various business models but may need add-ons for specifics. |

| Best-of-breed Capabilities | Offers best-of-breed capabilities with pre-integrated enterprise applications supported by SAP and third-party add-ons. | Features substantial best-of-breed options, including HCM, FP&A, CPQ, CRM, S&OP, TMS, RMS, and EHR. |

| Last-mile Capabilities | Limited pre-baked last-mile capabilities, may need development or add-ons. | Limited last-mile capabilities may necessitate add-ons or consulting efforts. |

| Operational Functionalities | Enterprise-grade operational capabilities, limited to industry-specific features. | Versatile ERP system suited for diverse business models. |

| Integration Capabilities | Does not offer out-of-the-box integration with A&D-specific PLMs, configurators, and CPQ systems. | Pre-integrated with several best-of-breed options including last-mile capabilities for service-centric verticals, including construction, media, public sector, banks and insurance. |

| Manufacturing Capabilities | Supports complex manufacturing operations and product models, limited to industry-specific capabilities. | Not as penetrated in discrete manufacturing verticals but has a strong presence in pharma-centric verticals. |

| Pricing Model | FUE (Full Use Equivalent) | Named user-based with a multi-year contract. |

| Key Modules | 1. Financial Management 2. Sales 3. Procurement 4. Manufacturing Management 5. Supply Chain Management 6. Professional Services Automation 7. CRM | 1. Financial Management 2. Project Management 3. Procurement 4. Risk Management and Compliance 5. Enterprise Performance Management 6. Supply Chain and Manufacturing 7. ERP Analytics |

SAP S/4 HANA vs Oracle Cloud ERP Feature Comparison

Both platforms offer a plethora of features and functionalities designed to streamline business operations and enhance efficiency. In this feature comparison, we delve into particularly the distinct capabilities of SAP S/4 HANA vs Oracle Cloud ERP across various critical dimensions, providing insights to aid businesses in making informed decisions regarding their ERP selection. Thus, this section discusses features under each of the following modules. Particularly financial management, supply chain management, and manufacturing management.

Financial Management Comparison

In this section, we are discussing a detailed comparison of the financial management capabilities particularly offered by SAP S/4 HANA vs Oracle Cloud ERP. By examining their respective strengths and functionalities, particularly in managing financial processes businesses can therefore gain valuable insights to determine the best-suited ERP solution.

| SAP S/4 HANA | Oracle Cloud ERP | ||

| Financial Management | General Ledger | Can support the needs of even the most complex financial organizations with more than ten ledger rollups at the country level and conversions. | Enterprise-grade ledgers to support multi-country operations at the global level with layers of sub-ledgers and complex closing process. |

| Accounts Receivable and Accounts Payable | Supports global collaboration of customers and vendors, including shared service model. | Support for complex, global AR and AP processes, including shared services. | |

| Cash Flow Management | Complex treasury capabilities with the support for global operations, including maintaining treasury KPIs, workflows, and processes for dedicated treasury departments. | Enterprise-grade capabilities for cash and treasury management. | |

| Currency Management | Can support complex currency workflows such as hedging and planning for current impact on different financial statements and accounts globally. | It ensures accurate handling of multi-currency transactions, allowing organizations to manage currency exposures effectively and maintain financial control. | |

| Tax Management | Has built-in support for taxes of over 100 countries. | Simplifies tax management by integrating tax systems, automating calculations, and ensuring compliance. |

Supply Chain Management Comparison

In this comparison, we explore and analyze the supply chain management capabilities of SAP S/4 HANA vs Oracle Cloud ERP, shedding light, particularly on their respective strengths and weaknesses.

| SAP S/4 HANA | Oracle Cloud ERP | ||

| Supply Chain Management | Warehouse Management | Can support embedded or standalone architectural patterns along with complex business models such as 3PL or warehouse value-added services for third-party logistics. | Streamlines warehouse operations, enhances inventory management, and ensures seamless multichannel fulfillment, end-to-end inventory visibility, and integration with advanced features for efficient resource allocation and workflow optimization. |

| Service Management | Can support complex quotes and service scheduling workflows of globally operated companies with large crews of field workers with scheduling dependencies of global operations. | Ensures efficient and effective service delivery through features like service request management, incident handling, and knowledge management. | |

| Inventory Management | Robust inventory management capabilities accommodating many different business models and inventory types of complex, global organizations. | Enables efficient management of goods flow, including inbound, within the warehouse, and outbound, while also supporting consigned inventory capabilities. | |

| Purchase Order Management | Complex purchase order management workflows with automated approval rules, multiple layers of hierarchies of global organizations with procurement processes integrated with project management, and MRP engines. | Helps organizations digitally manage and process purchase orders for supply chain and procurement activities, improving efficiency and reducing overhead costs. | |

| Requisition Management | Ability to manage complex requisition management processes of globally complex enterprises. | Allows users to efficiently view, create, submit, edit, and manage requisitions, ensuring proper approval workflows and seamless procurement processes. |

Manufacturing Management Comparison

In this comparison, we explore and analyze the manufacturing management ERP capabilities of SAP S/4 HANA vs Oracle Cloud ERP, shedding light, particularly on their respective strengths and weaknesses.

| SAP S/4 HANA | Oracle Cloud ERP | ||

| Manufacturing Management | Production Planning | One of the most complex planning capabilities with enterprise-grade strategies to optimize production cycles for global companies. | Offers production planning capabilities including capacity planning, MRP, shop floor control, and demand planning. |

| BOM and Routing | Enterprise-grade BOM scalability for a variety of business models and products. | Allows you to define lists of components associated with a parent item and outlines step-by-step operations required for manufacturing an assembly. | |

| Advanced Planning and Scheduling | Enterprise-grade advanced APS capabilities for complex globally distributed planning workloads that need to be collaborated across geographies. | Plans all supply chain facilities, supporting both short-term detailed scheduling and long-term aggregate planning within a single plan. It also considers finite capacity constraints and offers holistic optimization capabilities. |

Pros of SAP S/4 HANA vs Oracle Cloud ERP

When evaluating ERP solutions, understanding the distinct advantages of SAP S/4 HANA vs Oracle Cloud ERP is crucial. In this section, we are particularly exploring the strengths of SAP S/4 HANA vs Oracle Cloud ERP across various dimensions. Thus, shedding light on their respective capabilities and functionalities.

| SAP S/4 HANA | Oracle Cloud ERP |

| It is an ideal solution as the corporate financial ledger for global companies with multiple layers of financial hierarchies operating in multiple countries. | The product architecture supports the needs of large complex financial organizations with deep sub-ledger hierarchies. |

| The item master, product model, and warehouse architecture can accommodate the needs of most manufacturing business models. | Oracle Cloud ERP has an ecosystem of experienced consultants capable of handling the architecture of such complex enterprises. |

| Because of the power of HANA, SAP S/4 HANA can process very complex MRP runs with product models containing millions of serial numbers and SKUs, making it much faster than most ERP systems. | The embedded HCM and CRM processes are suitable for large non-profit organizations. The P2P workflows are friendlier for the indirect procurement needs of non-profit organizations. |

| Ideal fit for complex operations with its transactional maps capabilities built with the products, making debugging complex financial enterprises easier. | The workload Oracle Cloud ERP is designed to process millions of GL entries per hour. |

Cons of SAP S/4 HANA vs Oracle Cloud ERP

Just like recognizing strengths is important, it’s also crucial to weigh the specific drawbacks of SAP S/4 HANA vs Oracle Cloud ERP. Therefore, in this section, we will delve into the limitations and challenges associated with SAP S/4 HANA vs Oracle Cloud ERP across various operational and financial dimensions.

| SAP S/4 HANA | Oracle Cloud ERP |

| The controls provided as part of the product may feel unnecessary and overwhelming for smaller companies. | While functionally capable, transactional and financial traceability might not be as intuitive for large, complex enterprises. |

| Overbloated financial control processes which are only necessary for large organizations. | The data model and translations required to be successful with the product may be too overwhelming for smaller companies. |

| The data model is overwhelming for smaller organizations outgrowing QuickBooks or smaller ERP systems. | Might struggle with the complex MRP runs. |

| Despite advanced financial traceability and technical capabilities, the functional capabilities are not as rich as with its on-prem version. | Longer time in customizing and configuring the software design. |

| The best-of-breed solutions might not be as pre-integrated as other solutions. | The P2P processes, CPQ, and manufacturing capabilities may not be the friendliest for product-centric organizations. |

| In industries where it might not be the most frequently installed as an operational solution, the other solutions are likely to have deeper last-mile capabilities. | Limited last-mile functionality for DSCSA compliance, which will require an add-on or custom development. |

Conclusion

In conclusion, the choice between SAP S/4 HANA vs Oracle Cloud ERP hinges on the specific needs and priorities of your organization. SAP S/4 HANA stands out as the top choice for large enterprises particularly with complex global operations and extensive localization requirements across multiple continents. Also, its robust transactional workflow capabilities, purpose-built to streamline traceability for large and complex organizations, make it an ideal fit for companies seeking best-of-breed architecture tailored to specific functions. Moreover, SAP S/4 HANA excels in accommodating diverse operational needs, offering superior capabilities for areas such as warehouse management, HCM operations, and eCommerce platforms.

On the other hand, Oracle Cloud ERP is preferred by large enterprises across diverse industries, particularly those in service-centric verticals such as media, telecommunications, construction, and healthcare. Its strength lies in robust financial capabilities, hierarchical financial reporting, and also seamless integration with powerful HCM and EPM solutions. However, Oracle Cloud ERP may not be as suitable for product-centric industries or smaller companies due to its complex financial control processes and overwhelming data model. Ultimately, the decision between SAP S/4 HANA and Oracle Cloud ERP depends on factors such as the size of your organization, industry vertical, global footprint, and specific operational requirements. Hence, seeking assistance from an independent ERP consultant can significantly aid the decision-making process, offering specialized advice and direction tailored to the specific needs of the business and how they correspond with the key features of both products.